What is a release liner?

A release liner is a backing with a controlled surface—typically silicone‑treated—to protect adhesives on sheets and tapes. When the substrate is paper, it is called release paper; when it is film, release film.

Common uses include protecting the adhesive side of double‑sided tapes and stickers, and the medicated surface of adhesive bandages and patches.

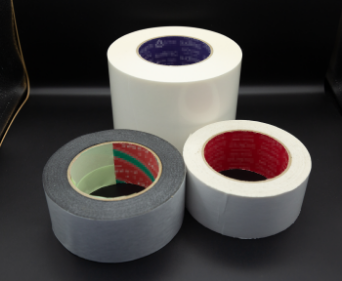

Our  release paper lineup offers high performance and quality across a wide range of specifications to meet diverse adhesive and bonding needs.

release paper lineup offers high performance and quality across a wide range of specifications to meet diverse adhesive and bonding needs.

We are committed to providing products that deliver real value for our customers.

Note: The generic term is release liner; paper‑based products are release paper and film‑based products are release film.

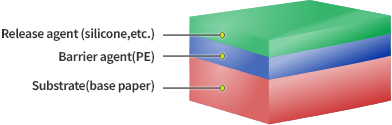

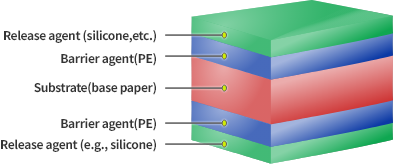

A release liner consists of a laminate of a release‑agent layer, a barrier layer, and a substrate layer.

-

Release agent (e.g., silicone).

Silicone resins are used in most cases; non‑silicone types are applied for certain applications.

-

Barrier layer (PE):

polyethylene (PE) is often used to prevent the release agent from penetrating the paper.

-

Substrate (base paper):

wood‑free paper, kraft paper, glassine paper, etc.

Because release agents are liquids, coating them directly onto paper allows penetration into the sheet, reducing release performance.

To prevent penetration, a polyethylene barrier layer is placed between pulp fibers to seal the pores.

Silicone is mainly used as the release agent; non‑silicone types are selected for certain electronics applications where silicon (Si) is undesirable.

Our Release Liner is used in

various occasions of daily lives.

- Automobile

- Smart Phone

- Sticking plaster / Adhesive medicine

- Wallpaper

- Marking film

- Building materials

- Stationery / general goods

- Flexible printed circuit(FPC)

- etc.

-

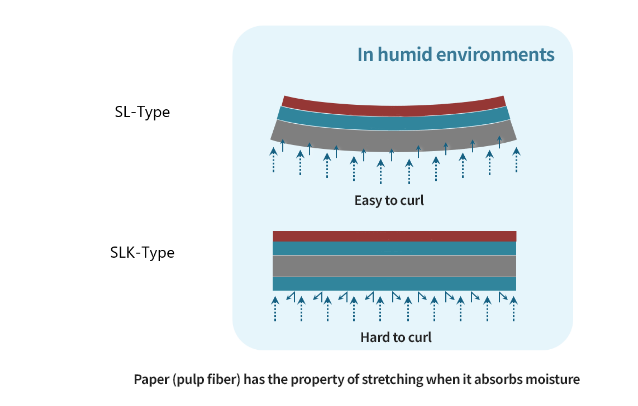

SL type

Single‑sided release liner

-

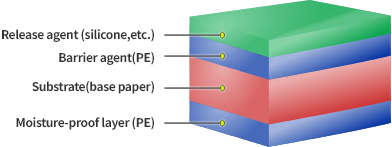

SLK type

Single‑sided release liner with PE‑laminated back

-

SLB type

Double‑sided release liner

Single‑sided release liner

-

Structure

Silicone / PE / Base paper

-

Base paper color

White, cream, blue, brown, light brown

-

Basis weight (base paper)

50g/m2–120g/m2

-

Release liner thickness

75μm–285μm

-

Basis weight (release liner)

65g/m2–160g/m2

-

Main applications

Kraft paper‑backed

adhesive tape; process paper; labels; sticker backing paper -

Features

- High quality

- Light release

- Very low migration

- Exposure resistance

- Product example(s)

- Single‑sided release liner — SL‑70SU2

- Structure

- Silicone / PE / semi‑bleached kraft paper (70g/m2)

Typical characteristics

| Item | Measured value | Test method |

|---|---|---|

| Total thickness (μm) | 110 | JIS P‑8118 |

| Basis weight (g/m2) | 90 | JIS P‑8124 |

| Tensile strength (kN/m) | MD 4.5 / CD 2.5 | JIS P‑8113 |

| Tear strength (mN) | MD 650 / CD 750 | JIS P‑8116 |

| Release strength (N/m) | 8 | *Note 1 |

| Residual adhesion ratio (%) | 90 | *Note 2 |

*Note 1

Adhesive: Oribain BPS‑8170

Laminating paper: wood‑free paper 78g/m2

Peel speed: 5 m/min

Peel angle: 180° (tape release)

*Note 2

Standard tape: Nitto 31B

Standard substrate: stainless plate (#280)

Peel speed: 0.3 m/min

Peel angle: 180°

These are representative values, not specifications. Peel load and residual adhesion rate vary with test conditions—please verify quality under your own conditions before use.

Single‑sided release liner with PE‑laminated back

-

Structure

Silicone / PE / Base paper / PE

-

Base paper color

White, cream, blue, brown, light brown

-

Basis weight (base paper)

50g/m2–120g/m2

-

Release liner thickness

90μm–220μm

-

Basis weight (release liner)

75g/m2–180g/m2

-

Main applications

Marking sheet, labels, wallpaper

-

Features

- Good curl resistance

- Light to medium release

- Non‑migration

- Exposure resistance

- Product example

- Single‑sided release liner with PE‑laminated back — SLK‑70AW

- Structure

- Silicone / PE / Wood‑free paper (70g/m2) / PE

Typical characteristics

| Item | Measured value | Test method |

|---|---|---|

| Total thickness (μm) | 110 | JIS P‑8118 |

| Basis weight (g/m2) | 105 | JIS P‑8124 |

| Tensile strength (kN/m) | MD 6.5 / CD 4.5 | JIS P‑8113 |

| Tear strength (mN) | MD 500 / CD 500 | JIS P‑8116 |

| Release strength (N/m) | 15 | *Note 1 |

| Residual adhesion ratio (%) | 98 | *Note 2 |

*Note 1

Adhesive: Oribain BPS‑8170

Laminating paper: wood‑free paper 78g/m2

Peel speed: 5 m/min

Peel angle: 180° (tape release)

*Note 2

Standard tape: Nitto 31B

Standard substrate: stainless plate (#280)

Peel speed: 0.3 m/min

Peel angle: 180°

These are representative values, not specifications. Peel load and residual adhesion rate vary with test conditions—please verify quality under your own conditions before use.

Good curl resistance of SLK type

An SL (single‑sided) liner has paper on one side. Paper absorbs atmospheric moisture and expands—so it tends to curl.

To mitigate curl, the SLK type laminates PE as a moisture‑proof layer on the back.

SLK is used where curl resistance is important, such as wallpaper and marking sheets.

Double‑sided release liner

-

Structure

Silicone / PE / Base paper / PE / Silicone

-

Base paper color

White, cream, blue, brown, light brown

-

Basis weight (base paper)

50g/m2–120g/m2

-

Release liner thickness

90μm–220μm

-

Basis weight (release liner)

75g/m2–180g/m2

-

Main applications

Various double‑sided tapes

-

Features

- Stable differential release from low to high peel speeds

- Less time‑dependent change in release strength

- Non‑migration

- Product example

- Double‑sided release liner — SLB‑80WD (#1300)

- Structure

- Silicone / PE / Wood‑free paper (78g/m2) / PE / Silicone

Typical characteristics

| Item | Measured value | Test method |

|---|---|---|

| Total thickness (μm) | 125 | JIS P‑8118 |

| Basis weight (g/m2) | 115 | JIS P‑8124 |

| Tensile strength (kN/m) | MD 9.0 / CD 6.0 | JIS P‑8113 |

| Tear strength (mN) | MD 550 / CD 550 | JIS P‑8116 |

| Release force (strength) (N/m) | inside 52 / outside 25 | *Note 1 |

| Residual adhesion ratio (%) | inside 98 / outside 98 | *Note 2 |

*Note 1

Adhesive: Oribain BPS-8170

Laminating paper: Wood-free paper 78g/m2

Peeling speed: 5m/min

Peeling angle: 180°(tape release)

*Note 2

Standard tape: Nitto 31B

Standard board (Substrate): stainless platel (plate) (#280)

Peeling speed: 0.3 m/min

Peeling angle: 180°

These values are representative values, not standard values. Peel load and residual adhesion rate vary greatly depending on the measurement conditions, so please check the quality under your own conditions before use.

SLB type — differential release behavior

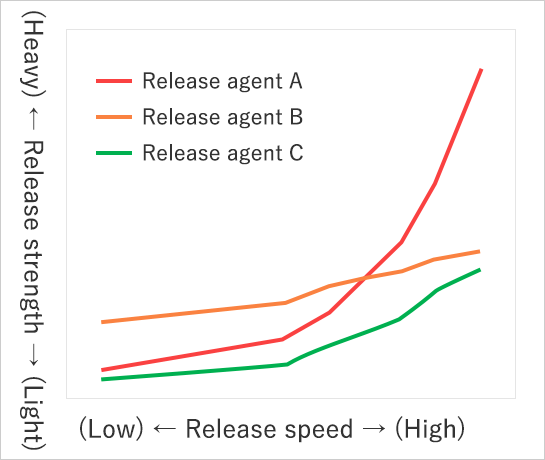

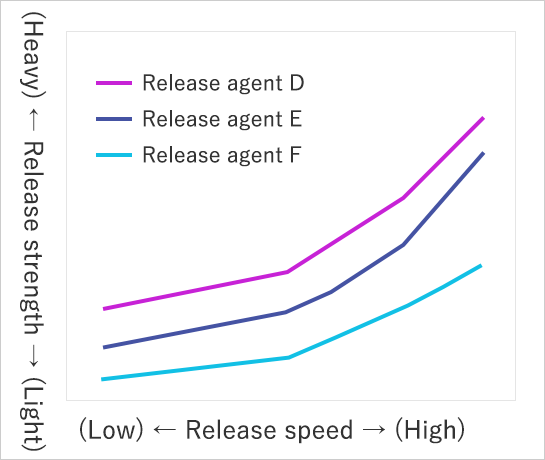

In silicone release liners, peel load generally increases with peel speed. Because speed dependence varies by release‑agent/adhesive pairing, the heavy and light sides can invert at certain speeds—risking tear‑off defects (see left figure, agents A and B).

Therefore, when designing double‑coated systems, we select release agents to match the customer’s adhesive and ensure consistent differential release—no inversion of peel load—across the expected peel‑speed range (see right figure).

About our release liner

We offer a wide range of release agents and base materials (base paper). By combining these with PE surface finishes—matte / semi‑matte / mirror—we provide a broad lineup of products.

| SL type Single‑sided release liner |

SLK type Single‑sided release liner with PE‑laminated back |

SLB type Double‑sided release liner |

|

|---|---|---|---|

| Structure |

Release agent (silicone, etc.) Barrier layer (PE) Substrate (base paper) |

Release agent (silicone, etc.) Barrier layer (PE) Substrate (base paper) Moisture‑proof layer (PE) |

Release agent (silicone, etc.) Barrier layer (PE) Substrate (base paper) Barrier layer (PE) Release agent (silicone, etc.) |

| Features |

Light release Very low migration Exposure resistance |

Good curl resistance Light to medium release Non‑migration Exposure resistance |

Stable differential release from low to high peel speeds Less time‑dependent change in release strength Non‑migration |

| Examples of use |

Kraft paper‑backed adhesive tape Process paper Labels Sticker backing paper |

Marking sheet Wallpaper |

Various double‑sided tapes |

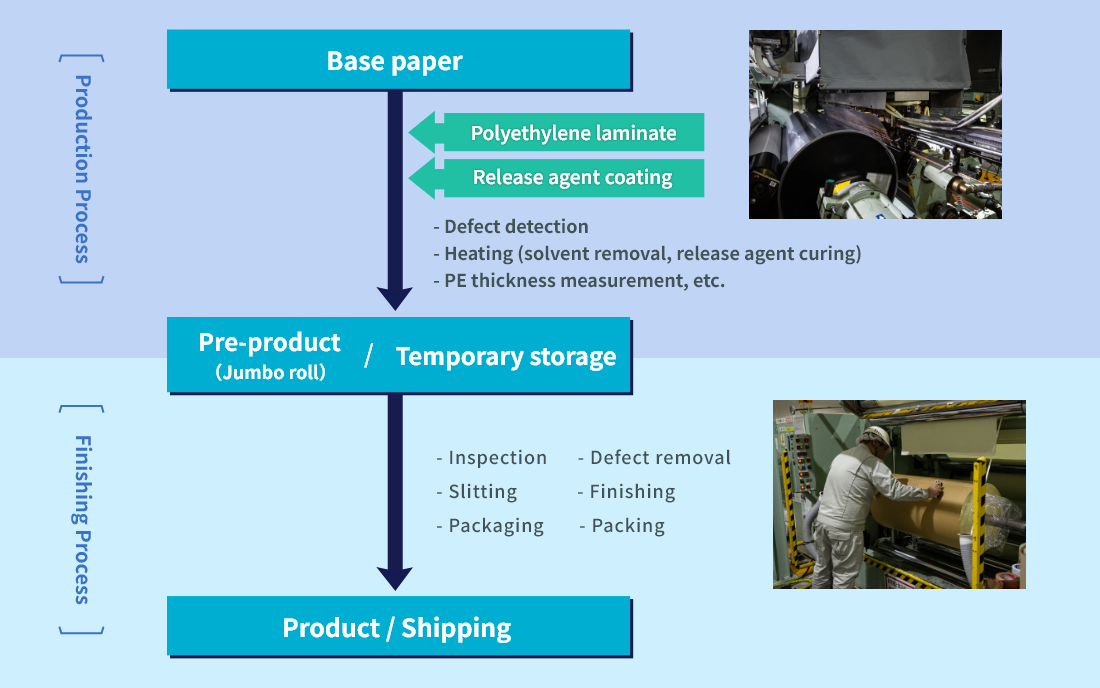

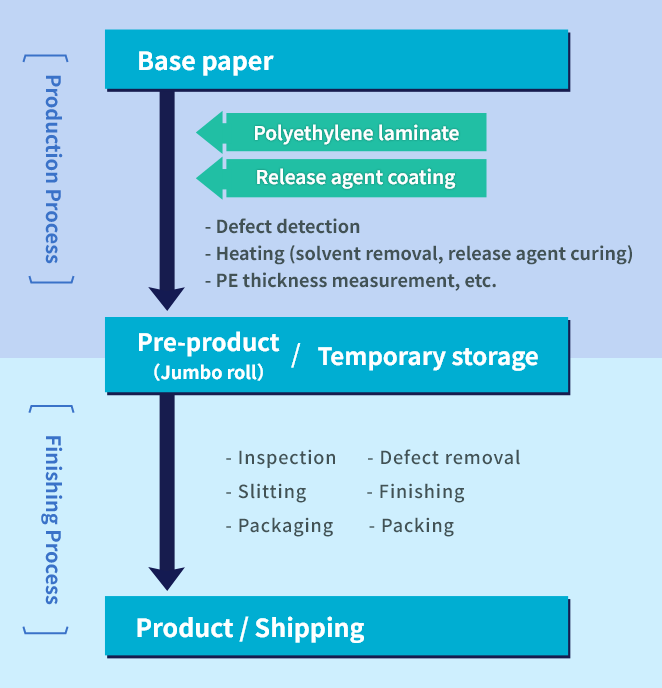

Release paper manufacturing

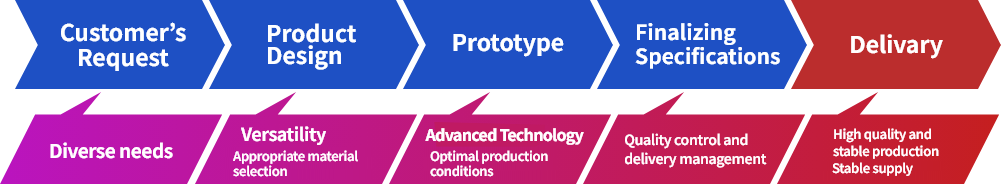

Sumilease: from development to supply

We meet diverse requirements—from light to heavy release and across base‑paper types.

We also support small lots and short lead times.

Order units: please contact us.

Base papers include kraft, Clupak, crepe, glassine, etc., selectable by application (other bases available on request).

We also offer base‑paper colors such as white, blue, cream, brown, and light brown.