Developer Development engineer interview Perforation Technology

Interview development engineer

Perforation Technology

-

First, could you briefly introduce yourself?

-

Development Engineer K

Development Engineer KI’ve been with the company for 27 years, working in Quality Control and Manufacturing Technology before joining the Technical Department. The “perforation” technology was a project I pursued while in Manufacturing Technology.

-

In which fields—and for what needs—is the perforation‑technology product used?

-

Development Engineer K

-

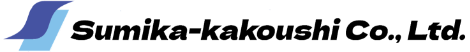

We developed release liners for adhesive films on automobile exteriors—especially pillars (window frames)—to replace conventional paint with films.

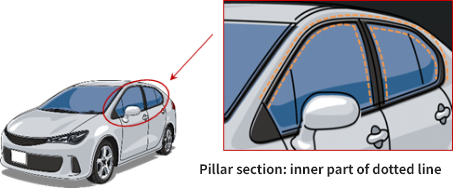

Adhesive films are made by coating adhesive on the release liner, heating to evaporate solvent, then laminating with a film substrate.

-

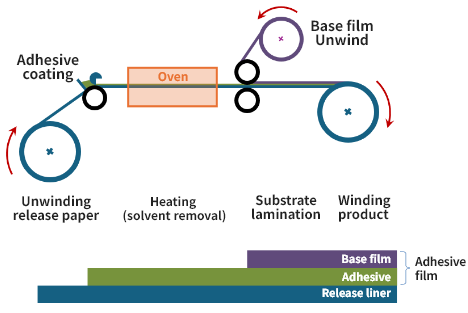

Because the film substitutes for paint, surface smoothness is critical—for the film substrate, the adhesive layer, and the release liner surface used for coating.

-

Could you elaborate on why smoothness is required for the release liner in paint‑substitution films?

-

Development Engineer K

-

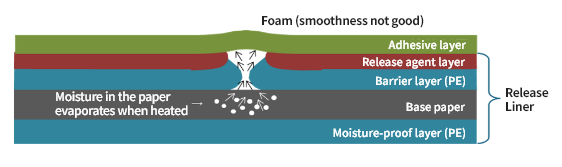

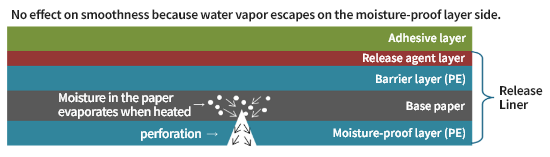

When heat is applied, moisture in the base paper vaporizes. With PE on both sides, steam has no escape path; the softened PE bulges where adhesion to the base paper is weak, causing foaming and pinholes that degrade smoothness and can lead to adhesive foaming.

-

So the “perforation” technology addresses these issues?

-

Development Engineer K

-

Exactly. We made shallow micro‑holes in the PE barrier layer (the side opposite the release surface) that do not penetrate through the sheet, venting steam toward the barrier side.

-

What challenges did you face during development?

-

Development Engineer K

-

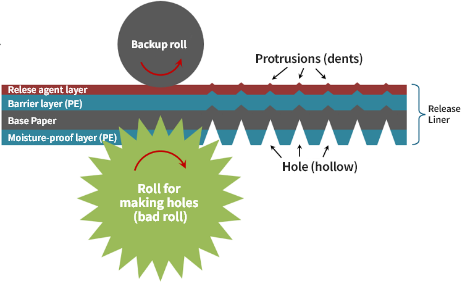

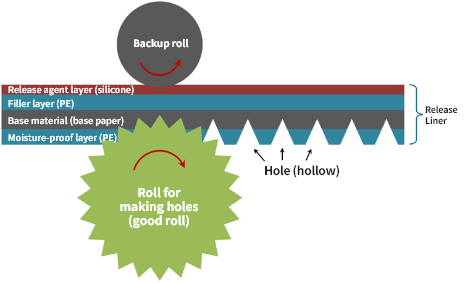

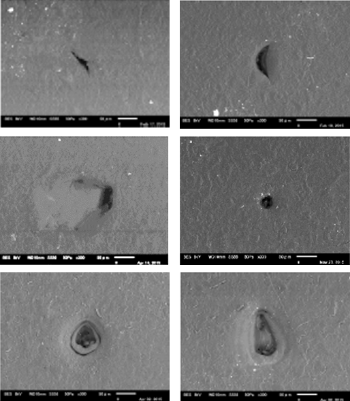

Physically perforating tends to mark the opposite release surface, harming smoothness. The toughest part was finding a roll that formed non‑through holes while keeping the release surface smooth.

-

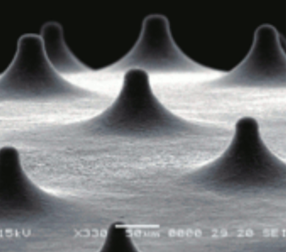

We tried many approaches, but marks remained—until we found that an etched protrusion pattern from Company N worked best, enabling completion of the product.

-

Was there a lot of trial and error before arriving at Company N’s protrusion shape?

-

Development Engineer K

-

Company N is not a roll maker; they specialize in etched protrusion shapes. We tried their approach and it worked. We etched protrusions onto plates and mounted multiple plates on a roll to make a perforation roll—a unique method that produced the ideal release liner.

-

Protrusion shape of N company’s roll surface product -

Photo of plate

-

-

Did you face any difficulties in practical implementation?

-

Development Engineer K

-

Yes. We had to retrofit the perforation roll onto the existing line, and fitting it into limited space was the hardest part.

-

Ensuring uniform perforation across the width must have been challenging as well…

-

Development Engineer K

-

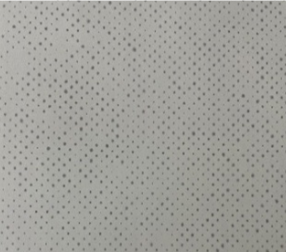

Indeed. We brought a sample with actual perforations. The holes are invisible to the naked eye, so we dyed the paper to reveal them. Uniform micro‑holes across the entire surface were achieved by optimizing conditions—backup‑roll selection and applied pressure.

Photo of dyed release liner

-

Finally, could you share a message from the development engineer’s perspective on this development?

-

Development Engineer K

-

This work led to Patent No. 6534961. We began in 2014, filed in 2016, refined the specifications, and launched in 2018—without major capital investment. Above all, it was a team effort; I’m grateful to everyone involved. Thank you.

-

Thank you very much.