Developer Development engineer interview Development of Non‑Silicone Release Liner

Interview development engineers

Development of Non‑Silicone Release Liner

-

To start, could you briefly introduce yourselves?

-

Development Engineer S

Development Engineer SI joined in April 2014. I was first assigned to the Technical Department to work on this product, and in September 2022 transferred to the Quality Control Section.

-

Development Engineer I

Development Engineer ISince joining in April 2018, I have been with the Technical Department.

-

First, where are non‑silicone release liners used, how are they applied, and how is the market evolving?

-

Development Engineer S

-

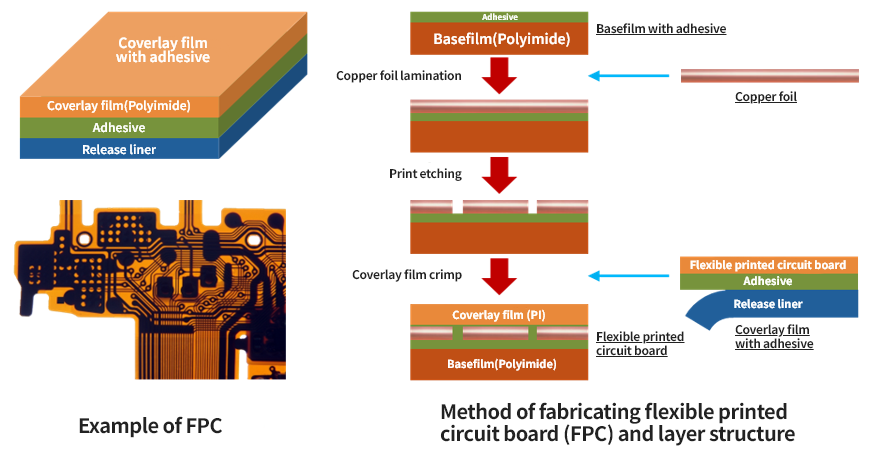

They are used mainly in electronics—for example, to protect the adhesive side of polyimide films in FPC (flexible printed circuit) applications. Because Si from silicone‑based liners can migrate into the adhesive and cause conductivity issues, non‑silicone release liners are used.

-

How did you approach development at our company?

-

Development Engineer S

-

Let me share a challenge we faced in the Technical Department and how we solved it. We observed heavy release—peel strength increasing over time—caused by reactions between the release agent and the adhesive. We considered how to prevent this defect.

We found that unreacted components remained on the release‑agent surface and reacted with the adhesive, leading to heavy release. -

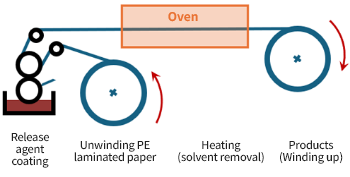

In manufacturing, after coating the release agent we heat in an oven to evaporate solvent and further heat to complete the reaction (curing). More heat advances the reaction, eliminating residuals and preventing heavy release.

-

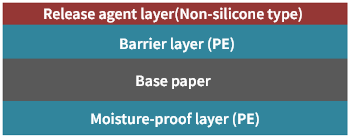

However, the barrier layer is polyethylene (PE) (melting point approx. 105–130℃). Excessive heat risks foaming, melting, loss of smoothness, and curl.

Structure of release liner -

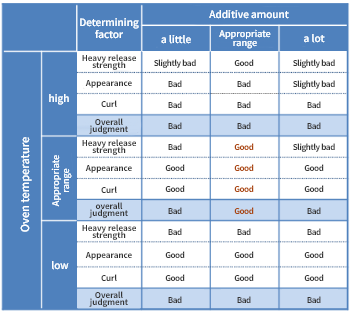

So we sought a method that removes residuals without excessive heat: add a small amount of an additive that reacts with the residual components to eliminate them.

-

What were the main challenges during your study?

-

Development Engineer S

-

First, identifying a low‑temperature‑reactive additive that fits our manufacturing conditions and suppresses heavy release required extensive screening.

Second, we had to determine the optimal dosage: too little leaves residuals; too much impedes the release‑agent reaction. Finding the balance was challenging but rewarding. -

With the right additive at the right level, we developed a release liner that maintains appearance and performance without heavy release in customer use.

-

This technology was also patented, correct?

-

Development Engineer S

-

Yes. We filed in 2016 (Japanese patent application 2018‑089955).

-

Next, Engineer I—could you describe how the non‑silicone lineup has expanded since this development?

-

Development Engineer I

-

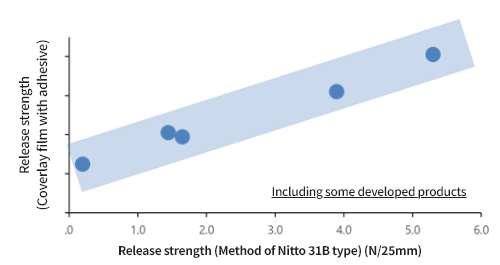

Historically, our non‑silicone lineup was limited, and we couldn’t always meet requests. We expanded release‑agent types to broaden the lineup, co‑developing new products with release‑agent suppliers.

-

What challenges did you encounter during the expansion?

-

Development Engineer I

-

Because release‑agent properties and concentrations vary, we must choose suitable diluents and set appropriate coating weights. We also work to ensure performance while keeping manufacturing conditions manageable for operators.

-

Finally, could each of you share your outlook?

-

Development Engineer I

-

We now offer non‑silicone release liners that cover a wide peel‑force range, and we’ll keep responding closely to customer needs.

-

Development Engineer S

-

From Quality Control, I believe daily quality maintenance and improvement lead directly to customer satisfaction. I want to contribute to high‑quality manufacturing.

-

Thank you very much.