Home > Products

is a high-quality release paper that can meet various customer needs for adhesive products. With its performance, we contribute to help our customers in various occasions.

is a high-quality release paper that can meet various customer needs for adhesive products. With its performance, we contribute to help our customers in various occasions.

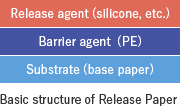

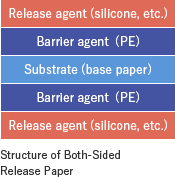

| Structure | Silicone/Polyethylene/Base paper/ Polyethylene/Silicone |

|---|---|

| Color of base paper | White, cream, blue, brown, light brown |

| Basis weight of base paper | 50g/m2-120g/m2 |

| Thickness of Release Paper | 90μm-220μm |

| Basis weight of Release Paper | 75g/m2-180g/m2 |

| Major application | Both-sided tape |

Example of product

Both-Sided Release Paper SLB-80WD(#1300)

Structure

Silicone/PE/Wood-free paper 78 g/m2/PE/Silicone

Characteristics

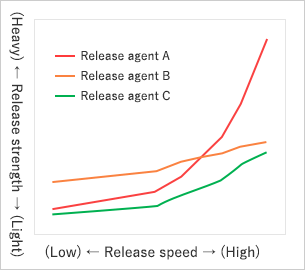

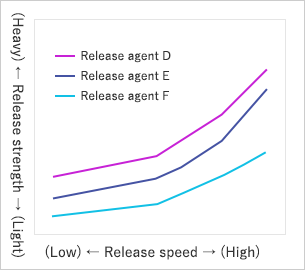

1.Stability in differential release strength from low to high speed

2.Less time-dependent change of release strength

3.Non-migration

Typical properties

| Item (unit) | Measurement value | Testing method |

|---|---|---|

| Total thickness (μm) |

122 | JIS-P-8118 |

| Basis weight of Release Paper (g/m2) |

117 | JIS-P-8124 |

| Tensile strength (kN/m) |

MD 9.0 CD 6.0 |

JIS-P-8113 |

| Tear strength (mN) |

MD 550 CD 550 |

JIS-P-8116 |

| Release strength (N/m) |

Internal surface: 52 External surface: 25 |

*1 |

| Residual adhesion rate (%) |

Internal surface: 98 External surface: 98 |

*2 |

The values shown above are representative values and not standard values. As release strength and residual adhesion rate may largely vary depending on the measurement condition, please check the product quality under your conditions.

Figure: Effects of release speed on release strength

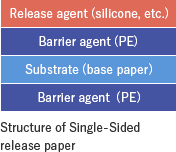

| Structure | Silicone/Polyethylene/Base paper/ Polyethylene |

|---|---|

| Color of base paper | White, cream, blue, brown, light brown |

| Basis weight of base paper | 50g/m2-120g/m2 |

| Thickness of Release Paper | 90μm-220μm |

| Basis weight of Release Paper | 75g/m2-180g/m2 |

| Major application | Marking films, Display labels |

Example of product

Single-Sided Release Paper with PE Laminated Back SLK-70AW

Structure

Silicone/PE(mirror)/Wood-free paper(white)70g/m2/PE(matt)

Characteristics

1. Light to medium release

2. Non-migration

3. Superior exposure resistance

Typical properties

| Item (unit) | Measurement value | Testing method |

|---|---|---|

| Total thickness (μm) |

110 | JIS-P-8118 |

| Basis weight of Release Paper (g/m2) |

105 | JIS-P-8124 |

| Tensile strength (kN/m) |

MD 6.0 CD 5.0 |

JIS-P-8113 |

| Tear strength (mN) |

MD 500 CD 500 |

JIS-P-8116 |

| Release strength (N/m) |

15 | *1 |

| Residual adhesion rate (%) |

98 | *2 |

The values shown above are representative values and not standard values. As release strength and residual adhesion rate may largely vary depending on the measurement condition, please check the product quality under your conditions.

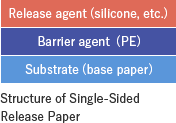

| Structure | Silicone/Polyethylene/Base paper |

|---|---|

| Color of base paper | White, cream, blue, brown, light brown |

| Basis weight of base paper | 50g/m2-120g/m2 |

| Thickness of Release Paper | 75μm-285μm |

| Basis weight of Release Paper | 65g/m2-160g/m2 |

| Major application | Process paper, adhesive tapes, labels |

Example of product

Single-Sided Release Paper SL-70S(U2)

Structure

Silicone/PE(mirror)/Semi-bleached Kraft paper 70g/m2

Characteristics

1. Light release

2. Slight migration

3. Superior exposure resistance

Typical properties

| Item (unit) | Measurement value | Testing method |

|---|---|---|

| Total thickness (μm) |

105 | JIS-P-8118 |

| Basis weight of Release Paper (g/m2) |

90 | JIS-P-8124 |

| Tensile strength (kN/m) |

MD 5.5 CD 2.0 |

JIS-P-8113 |

| Tear strength (mN) |

MD 700 CD 900 |

JIS-P-8116 |

| Release strength (N/m) |

8 | *1 |

| Residual adhesion rate (%) |

90 | *2 |

The values shown above are representative values and not standard values. As release strength and residual adhesion rate may largely vary depending on the measurement condition, please check the product quality under your conditions.

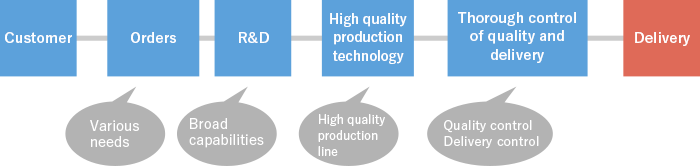

We respond to various quality requirements of our customers from light release to heavy release, types of base paper, etc. We can accept orders for small lots and deliver the product with short delivery time. Please consult with us for the unit of order.

Customers can choose base paper used as the substrate from kraft paper, clupak paper, crepe paper, glassine paper, etc., according to their needs. Customers can select the color of base paper from a wide range of options, including white, blue, cream, brown, and light brown.

Inquiries about our products

Inquiries about our products are accepted via email or phone calls. Please feel free to contact us.

Sales Division Tokyo Sales Group

INT'L TEL:+81-3-6837-9052